Your Cart is Empty

Japan has a rich history of swordmaking dating back to around 900 A.D. Historians believed that some of these early era swords were derived from ancient Chinese swords, as they featured similar designs and construction methods. From 987 to 1597, however, Japan had pioneered its own swordmaking craft, leading to the production of the tachi, katana, wakizashi and similar high-quality blades.

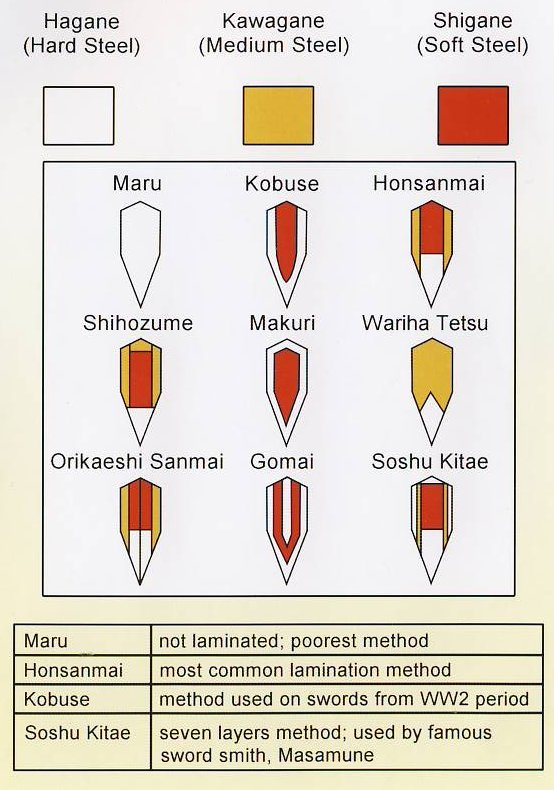

Japanese swordsmiths used a variety of techniques to create swords, including the use of multiple assembly types. In this post, we're going to explore some of the most common ways in which Japanese swords were assembled.

Maru

Also known as muku, maru is the most basic and most common type of assembly for modern-day Japanese swords. It involves the use of a single type of high-carbon steel to forge the blade. Modern swordsmiths prefer the maru assembly over other types because of its simplicity and ease of use. In the past, however, other assembly methods were preferred, including the kobuse.

Kobuse

A more popular type of sword assembly used in feudal Japan was the kobuse. While the maru assembly uses a single type of steel, kobuse uses two types of steel. Swordsmiths would use hagane steel for the sword's edge and shigane steel for the core. Short for tamahagane, hagane is exceptionally strong and durable type of steel, more so than shigane. By using it for the edge, swordsmiths were able to create swords with a superior level of performance; thus, popularizing the kobuse style of sword assembly.

Honsanmai

A third type of assembly used when making Japanese swords was the honsanmai. Like kobuse, it involves the use of hagane steel for the sword's edge and shigane steel for the core. However, it also adds another type of steel, kawagane, to the sides of the blade.

Shihozume

The shihozume is a type of Japanese sword assembly that's similar to honsanmai. Like its counterpart, shihozume requires the use of three different types of steel: shigane, higane and kawagane. The kawagane steel, however, is added to the sides as well as the bottom of the blade. Because of this, it's more difficult to use than some of the other assembly types, but the end result is a high-performance sword that can strike and flex without breaking under pressure.

These are just a few of the different assembly types used in traditional Japanese swords. There are literally dozens of other assemblies, each of which has unique characteristics.