Ihr Warenkorb ist leer

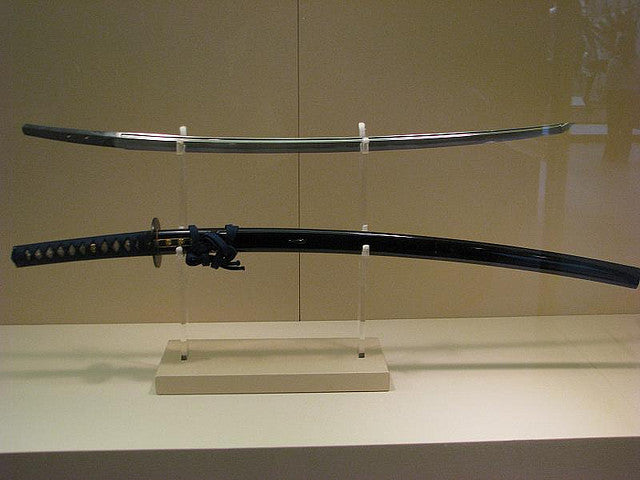

The katana has become one of the world's most iconic and recognizable swords. Originating in Japan, it features a curved, single-edged blade measuring between 23 and 28 inches (60 to 73 cm). While there have been countless types of katanas produced since it first appeared during Japan's Muromachi period (1392 to 1573), they all feature a curved blade. So, how did bladesmiths make the katana's curved blade exactly?

No, Bladesmiths Didn't Hammer the Katana Into a Curved Shape

Some people assume that the Japanese bladesmiths simply hammered the katana's blade into a curved shape. Hammering was a common process in bladesmithing, but it didn't influence the katana's curvature. Rather, Japanese bladesmiths would hammer swords for the purpose of folding the metal to create many layers. The idea behind hammering was to create blades out of multiple layers, thus increasing its strength while removing impurities from the metal in the process. Hammering, however, did not affect the shape of the katana's blade.

Differential Heat Treatment Is Responsible for the Katana's Curved Blade

The reason the katana has been traditionally made with a curved blade is because of differential heat treatment. We've talked about this before on our blog. In case you missed it, differential heat treatment is a bladesmithing process pioneered during feudal Japan. It involves heating and then cooling different parts of a blade at different rates. As one side cools more quickly than the other, differential heat treatment changes the physical properties of those two sides, forcing the blade to curve.

When forging a katana, bladesmiths would coat the spine in a thick layer of clay and the edge in a thinner layer of clay. Once coated, the bladesmith would quickly quench the still-heated katana in water or oil. Because of the spine's thick layer of clay, it would cool more slowly than the edge. Known as differential heat treatment, this forces the edge to bend into the spine, thereby creating the katana's curvature.

Differential heat treatment was also used to create a flexible spine. It's primary purpose, however, was to create the katana's curvature. Without differential heat treatment, the katana wouldn't have a curved blade.

What Happened to Straight, Non-Curved Katanas?

In feudal Japan, bladesmiths designed katanas specifically to have a curved blade. If a bladesmith performed differential heat treatment on a katana and it didn't create a curved blade, the bladesmith would typically discard the sword and start over again.