Votre panier est vide

You've probably heard of Japanese swords like the katana made of tamahagane steel. But what exactly is tamahagane steel?

Tamahagane Steel: The Basics

Tamahagane steel is a special type of rare steel used by traditional Japanese swordsmiths. It's characterized by a higher content of carbon; thus, allowing for a stronger blade.

Tamahagane steel typically contains around 1 to 1.5% carbon content. Achieving the correct level of carbon is essential, as too much makes the blade brittle. If there's not enough carbon, the blade won't hold an edge. Traditional Japanese swordsmiths have perfected the craft of making tamahagane steel with a precise concentration of carbon to overcome these obstacles.

How Tamahagane Steel is Made

In his book titled " Spirit Of The Sword: A Celebration of Artistry and Craftsmanship," author Steve Shackleford explains that the method for creating tamahagane steel differs from conventional steel.

The process begins by smelting multiple layers of charcoal and iron sand in a special clay vessel, known as a tatara. There are two types of iron sand used for this process: acome and masa, the latter of which offers a higher level of quality. Normally, a person called a murage is responsible for choosing the iron sand to make tamahagane steel.

The swordsmith separates the various types of carbon steel, including low-carbon steel ( hocho-tetsu) and high-carbon steel (tamahagane). Next, the swordsmith forges the tamahagane in alternating layers. During this process, the swordsmith may fold the steel as many 16 times. If tamahagane isn't folded, the heterogeneous distribution of carbon in metal will create weak points for the sword. (note: modern super alloy steels such as L6 steel that we use exclusively on our katanas and jingums are very homogeneous and does not require folding.)

It's important to note that tamahagane isn't the only metal used to forge traditional Japanese swords. Swordsmiths often use multiple types of materials produced in the tatara. The hocho-tetsu, for instance, is used to forge the core structure of the blade, whereas the high-carbon tamahagane is combined with pig iron to make the outer layer of the blade.

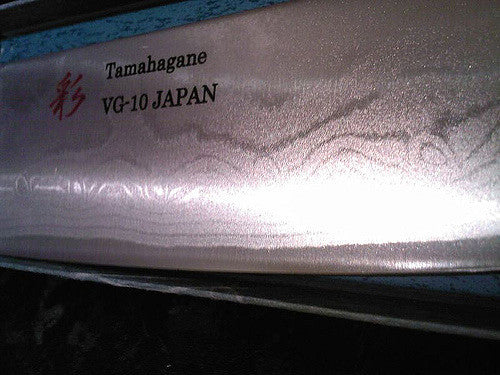

You can usually identify a high-quality tamahagane steel sword by looking for its characteristic bright silver/chrome color.

Today, tamahagane steel production is highly regulated by the Japanese government. It's currently illegal to export raw tamahagane steel before turning it into a ready-to-sell product. Furthermore, it's typically only made 3 to 4 times per year, making the metal exceptionally rare while also driving up costs for consumers. Note: Most tamahagane katanas marketed by Chinese sword manufacturers and their distributors are not real tamahagane but they are unregulated Chinese imitations with unknown quality control process.

Photo credit: Ian Seckington